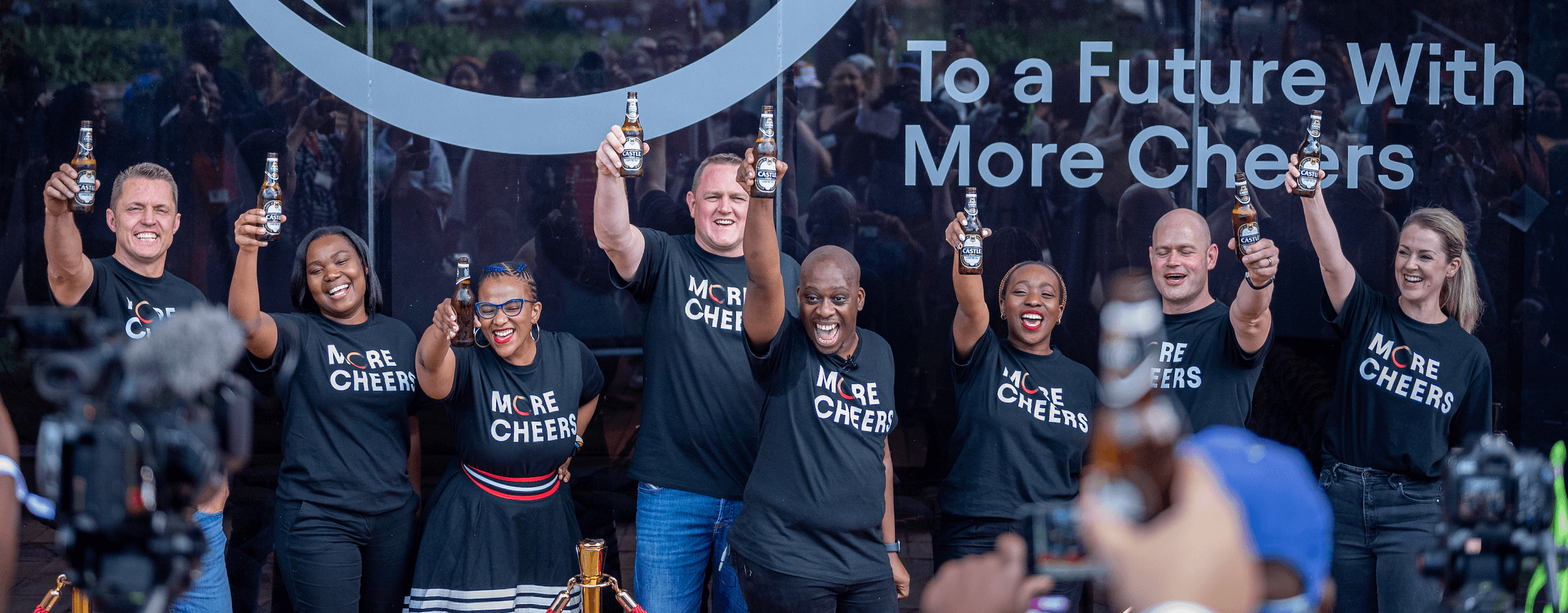

SAB celebrates South Africa’s big dreams and is committed to propel the country forward through the power of beer.

SAB Podcasts

The More Cheers Podcast

The More Cheers Podcast takes a deep dive into our brands, our people and our partners; as well as an in-depth look at how SAB continues to demonstrate the unique power of beer to propel South Africa forward towards a Future With More Cheers.

Stories We Are Telling

.

SAB tackles alien vegetation as part of its efforts to conserve water

In commemoration of World Water Day 2024, the South African Breweries has highlighted the adverse impact that alien vegetation has on water security for farmers, businesses and local communities in South Africa. Water scarcity remains a challenge for South Africa.

According to a report the country has half the average global rainfall and is projected to have a 17% water deficit by 2030.

South African Breweries (SAB) records top-line performance

In an announcement today (29 February), the South African Breweries (SAB) reported double-digit top-and high-single-digit bottom-line growth with record high full-year volumes for its financial year (FY) 01 January 2023 – 31 December 2023.

For the Full Year in 2023, revenue for SAB grew by the mid-teens with low-teens revenue per hl growth and a mid-single digit increase in volume. EBITDA grew by high-single digits, as top-line growth was partially offset by anticipated transactional FX and commodity cost headwinds.

SAB AND MOLETELE COMMUNITY PARTNERSHIP BEARS FRUIT IN LIME FARMING PARTNERSHIP

A lack of local supply of limes was affecting South African Breweries’ Corona beer’s authentic drinking ritual. The solution was a novel opportunity to invest in lime farming and in boosting local production, emerging farmers and their communities were significantly empowered.

Entrepreneur Empowerment through SAB Retail Academy Launch

Entrepreneurship is a key proof point of inclusivity. We meet entrepreneurs where they are today and work with them to get to where they want to be tomorrow Innovation and entrepreneurship part of the DNA at the South African Breweries (SAB), and its latest venture to empower just above 4500 retailers with business skills, is one such example. Launched during entrepreneurship month, the Retail Academy aims to empower retailers with skills, knowledge and tools to help their businesses thrive and operate as sustainable ventures.

SAB’s commitment to road safety unpacked at Road Safety Summit

The South African Breweries (SAB) recently participated in the 15th annual Road Safety Summit held on the 8 - 9 November, 2023 in Johannesburg. Themed, “Road safety is a shared responsibility,” the event saw stakeholders came together to address various approaches, including smart transport monitoring systems to ensure road safety in South Africa.

SAB Commits to nourishing communities on World Food Day

This World Food Day, the South African Breweries has once again partnered with the Western Cape Department of Agriculture (WCDOA) to host an event that aims to raise awareness of the world food shortage. . The event hosted dignitaries such as the Executive Mayor, Bitou Municipality, Cllr Dave Swart, District Mayor, Memory Booysen , the Western Cape MEC for Agriculture, Dr Ivan Meyer, Head of Department, Dr Mogale Sebopetsa and the Deputy Director General Mr Darryl Jacobs.,